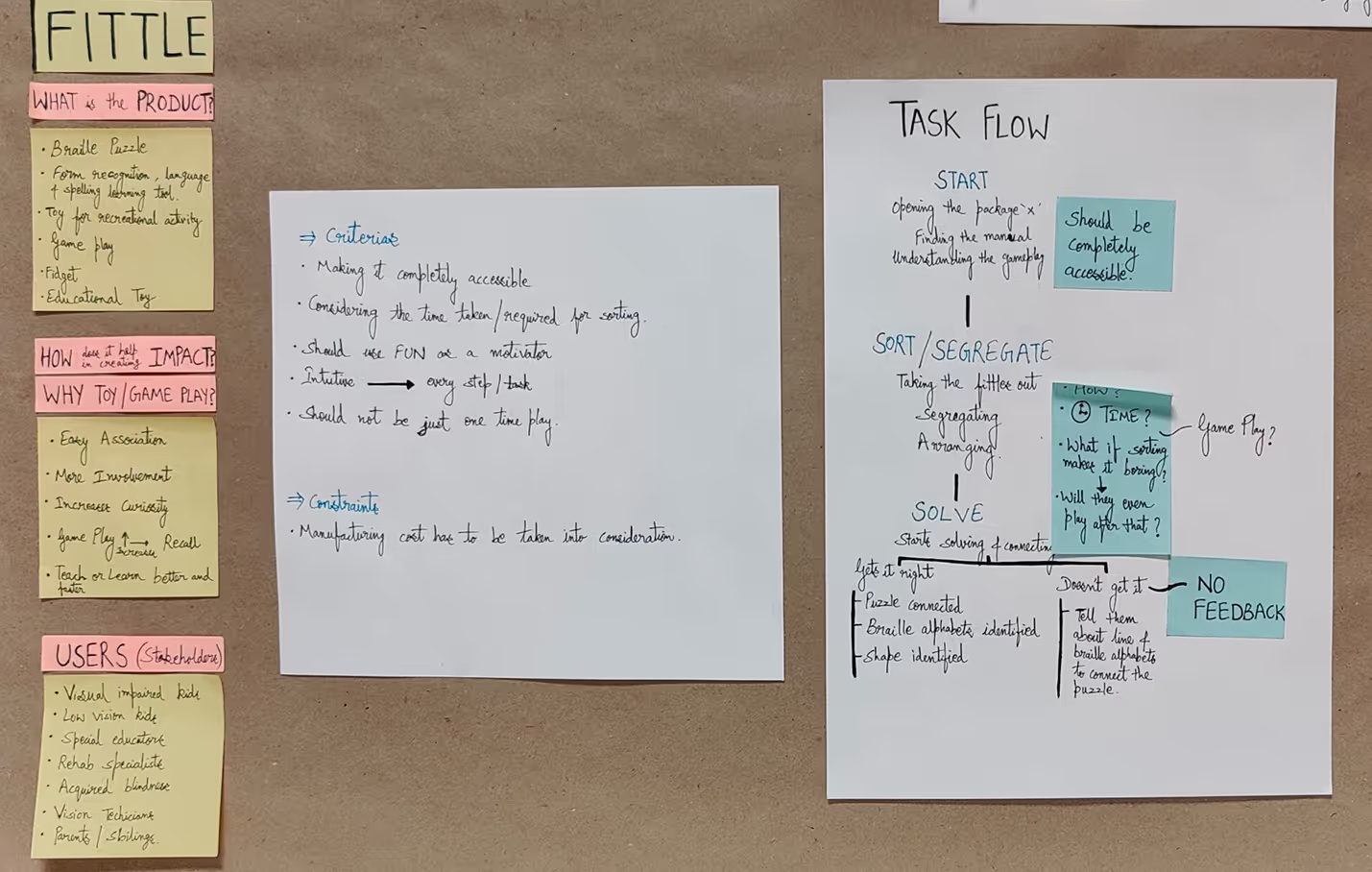

Fittle is world's first 3D-printed Braille puzzle which had a brilliant concept but failed in practice.

Through 8 months of research, iteration, and testing, I helped the team redesign it into a storytelling system that made 22 million visually impaired Indian’s path to literacy more joyful.

In India, 22 million people are visually impaired. Most can't read Braille, which limits employment. Traditional learning tools cost thousands of rupees and feels clinical – function over joy.

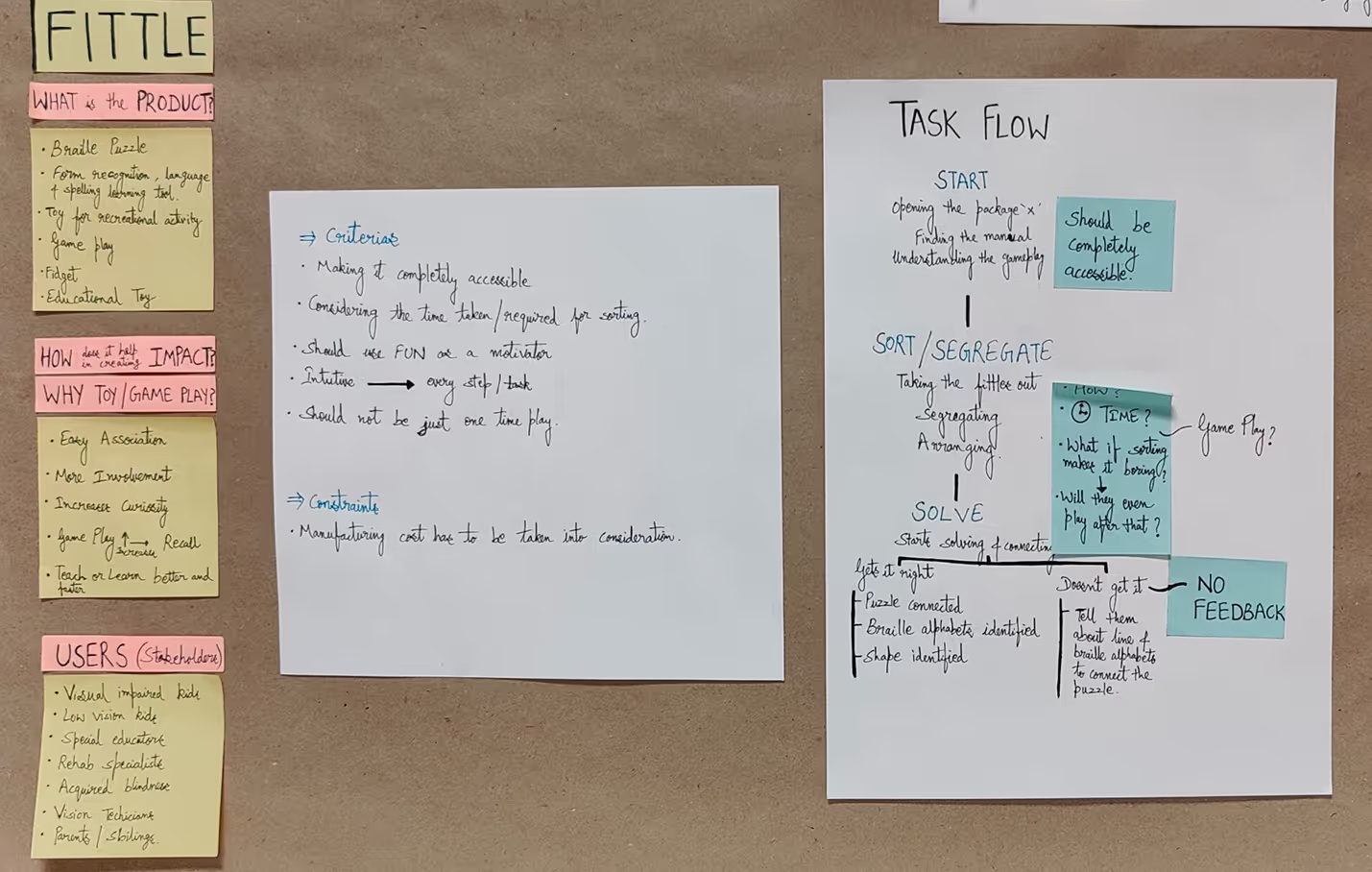

Fittle was conceived as a breakthrough: the world's first 3D-printed Braille puzzle. Each piece represents a letter, connected, they spell words and form tactile shapes. Brilliant concept. Low-cost. High impact potential.

But it had stalled.

The original version faced usability issues and failed to gain traction with schools and rehabilitation centers. So when I joined LV Prasad Eye Institute (LVPEI) as a design intern, my mandate was clear: Figure out why Fittle isn't working, and redesign it into something kids actually want to use.

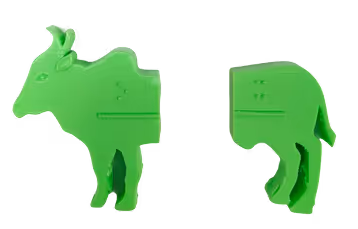

Form redesign wasn't about making things 'accessible' – it was about making shapes that tell stories through touch alone. Cultural familiarity + tactile clarity + gradual difficulty = objects kids could recognize, remember, and want to explore.

Bulky, vague shapes – hard to distinguish by touch

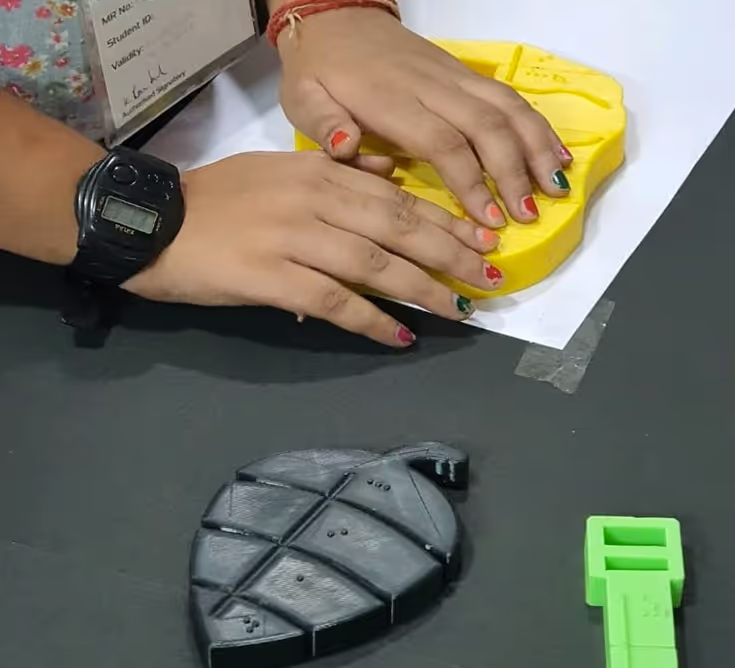

Tested different levels of

tactile detail

Bulky, vague shapes – hard to distinguish by touch

Every form has distinct features that can't be confused with others. Eg. OX: Distinctive horns (two upward curves from head) + four-legged stance + tail extension

Kids stopped asking "What is this supposed to be?" and started saying "Oh, this is a truck!" – immediate tactile recognition replaced guesswork

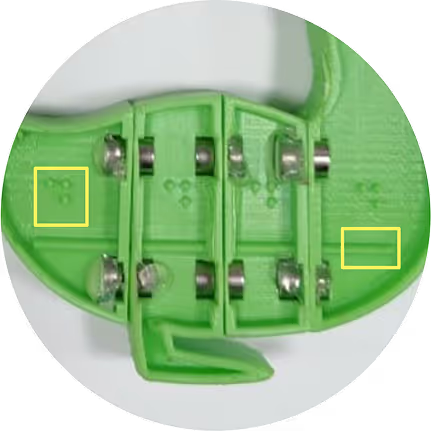

Phase 1's triangular connectors demanded perfect alignment – an impossible ask for touch-based assembly. Magnets transformed frustration into satisfaction, turning every connection into tactile feedback that whispered: "You got it right."

Magnets naturally pull pieces into correct position – no precise manual alignment needed. Kids feel the magnetic attraction guiding their hands.

Magnets create instant tactile + auditory feedback. That click = success. It's a dopamine hit. It says "you did it right" without words.

Magnets sit slightly above the surface (not flushed) to provide: Tactile landmarks for connection points, Pre-connection magnetic pull feedback, and clear indication of where pieces really join.

Reduction in assembly time. Magnetic self-alignment eliminated trial-and-error positioning.

Zero mid-assembly failures while assembling. No pieces fell apart during any testing session (vs. frequent disconnections in Phase 1)

External guides failed. Reference sheets confused. The breakthrough: make every piece carry its own instructions. A tactile line says "this way up." A Braille letter says "I belong to DUCK." Self-guided play emerges when objects teach you how to use them.

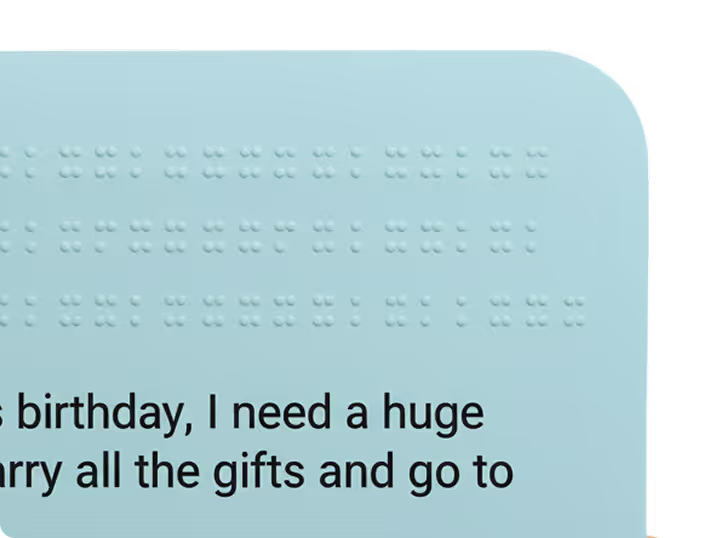

Kids could scan front for the name of the object and flip to back for navigation. Single raised line embossed on each piece helps to identify right orientation.

Orientation line = top edge

Braille identifier = center of back surface

Universal positioning across all puzzles allowed predictable wayfinding

Zero instances of incorrectly oriented pieces during assembly in Pilot Study 2

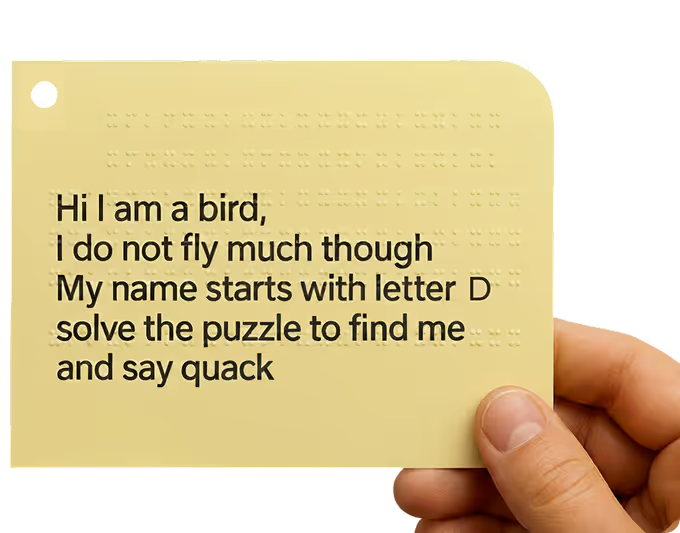

Storytelling didn't just add engagement – it fundamentally transformed what Fittle is. No longer a collection of tactile puzzles, but a narrative journey where every Braille letter unlocked the next chapter. Context creates meaning. Meaning creates memory. Memory creates learning that sticks.

Kids navigating by touch need to know card orientation before reading. Rounded corner on top-right = instant tactile cue. Feel for the curve, know which way is up, begin reading. Small detail, massive usability impact.

Rather than instructions ("Build a watch next"), we wrote curiosity hooks: "Duck wants to know the time – what should Duck find?" This shifts from directive (you must) to invitation (can you help Duck?). Kids became collaborators, not task-completers.

Kids added their own narrative details. The story framework invited creativity, not just consumption.

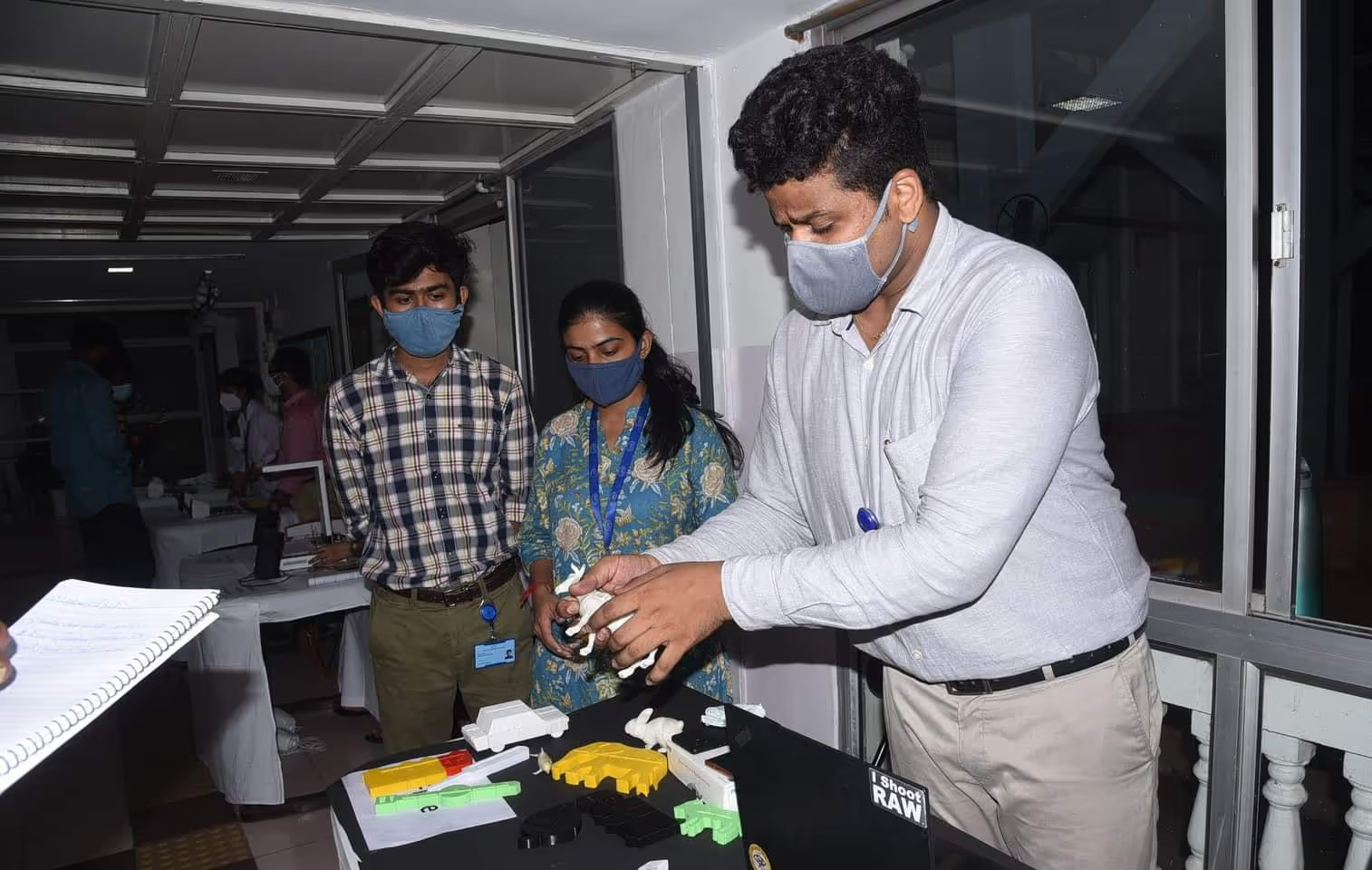

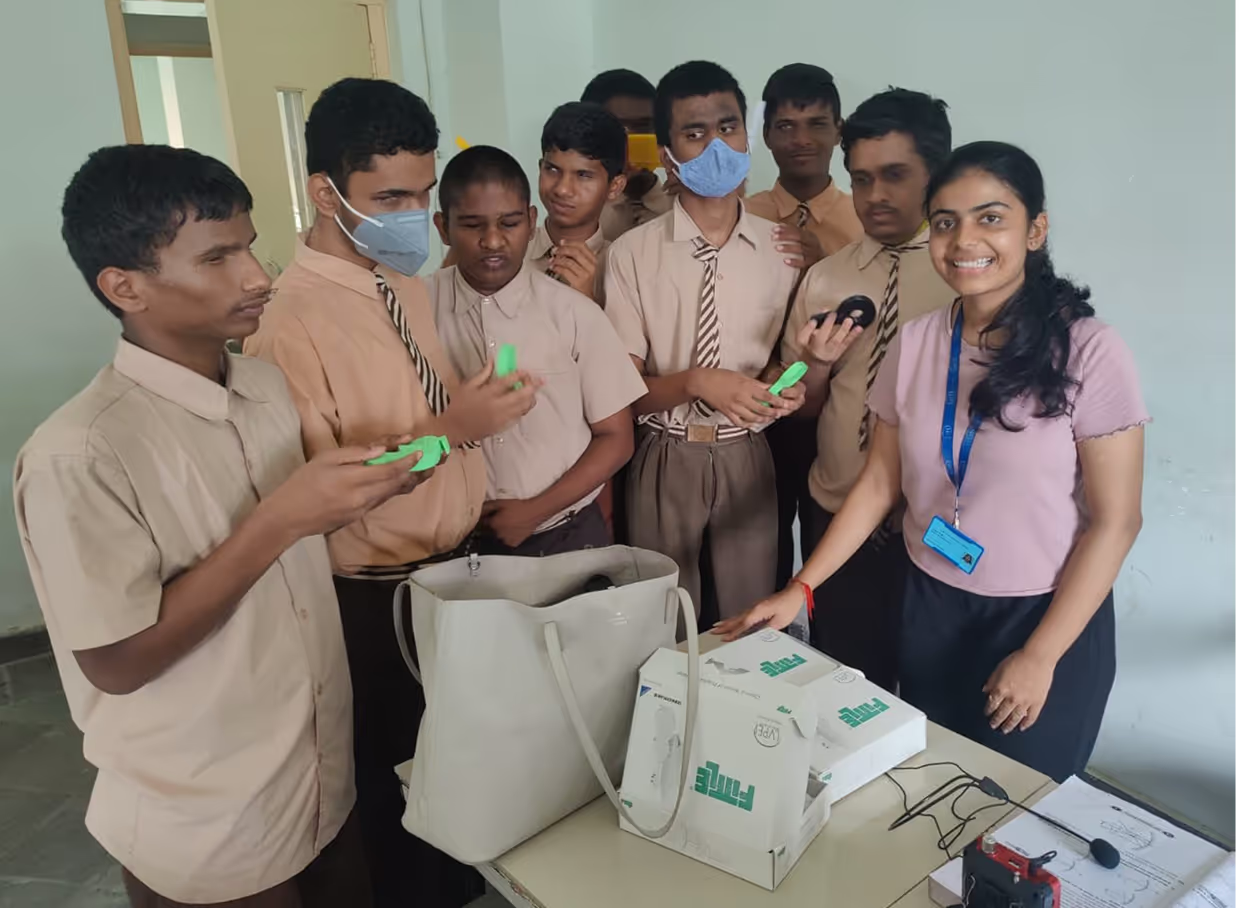

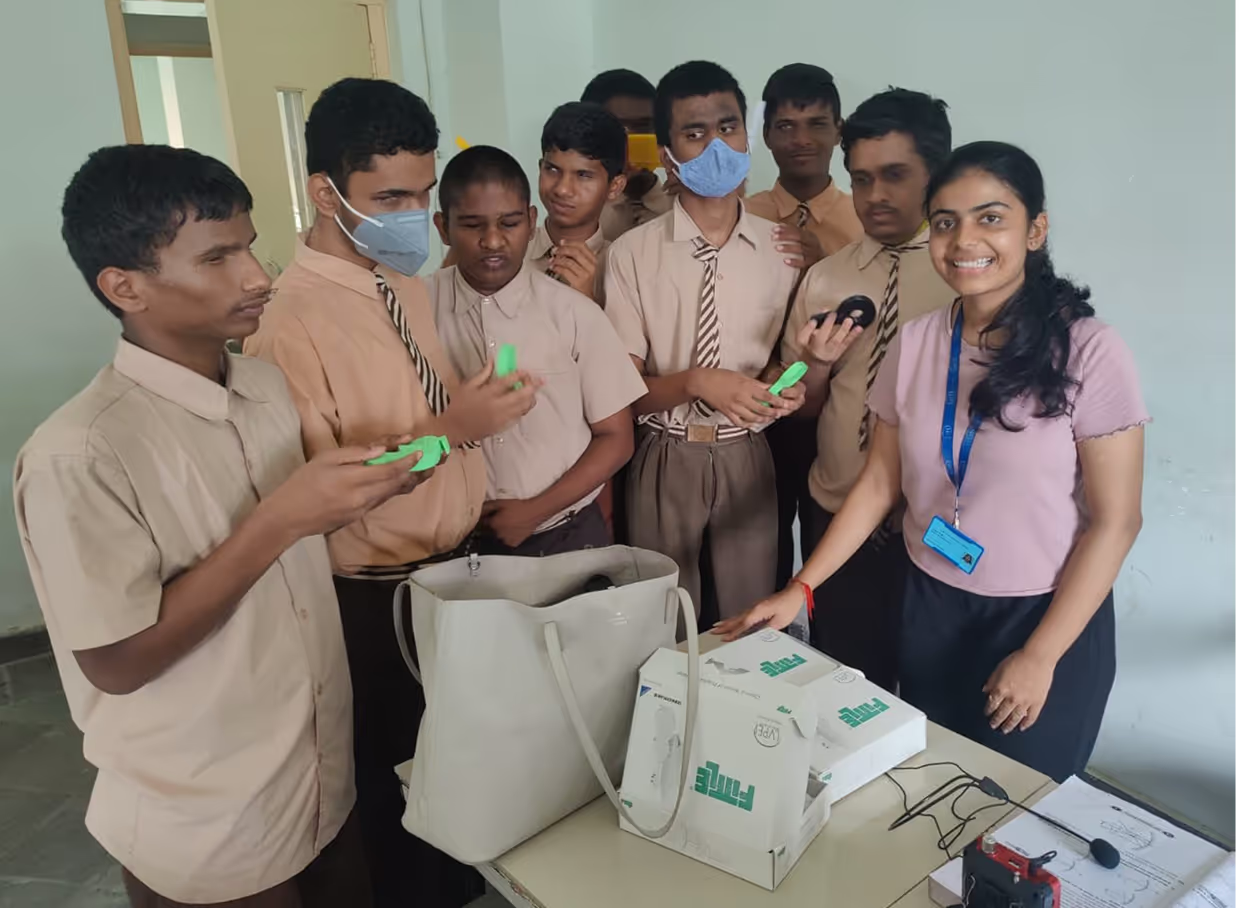

To create awareness about the available assistive technology that can help people with disabilities lead a quality and independent life to mark the Global Accessibility Awareness Day, on 19th May 2022 the team at LVPEI's Institute for Vision Rehabilitation organized an Assistive Technology Exhibition.

The event had several assistive technology products, TLM learning products and infrastructural accessibility for people with Vision Impairment to help them integrate into the mainstream society.

We got a chance to showcase Fittle to and talk about the learning opportunities it brings, beginning with fine motor activity to enhanced higher level cognitive functioning such as attention, focusing, problem solving, concept learning and many more.